Second mobility of the European Project ERASMUS+ SMARTRAIN in Italy

The SMARTRAIN project continues with its progress, and this time the second mobility was held in Italy, during the week of March 7 to 11 2021.

Students and teachers of the project, together with technical managers of the project partners, travelled to the headquarters of Enaip Lombardia in Cantu, Lombardy region, in northern Italy. There, a set of activities were carried out with the common link of 3D printing, teamwork and based on the projects that each of the groups are developing, and their usefulness for the wood-furniture sector.

During the mobility, Enaip Lombardia, coordinated by Sara Tettamanti, responsible for the International Area of this entity, organized an attractive schedule for this mobility within the project. Activities ranged from group dynamics/games to promote teamwork, to training activities on 3D, practical activities on 3D modelling on 3D printers and laser cutting equipment, including a series of visits to ENAIP’s FABLAB facilities, to two local companies: TABU and RIVA 1920, and to the Polytechnic University of Milan.

The working sessions were held in ENAIP’s FABLAB, with an initial contact with the areas available to the users of this ENAIP centre.

This space has three different areas:

- An event area to host meetings and workshops on design and wood design.

- A cultural area with 3 important furniture design collections “Neoliberty e Dintorni” and “Mobili come aforismi – 35 mobili del razionalismo italiano” belonging to Federlegno Arredo eventi spa, Collezione “Bruno Munari” belonging to the Municipality of Cantù and the Associazione Amici dei Musei di Cantù. There is also a library with over 3,000 magazines, 2,000 books and publications on wood and wood design area.

- An experimentation area where there is the ToMake FabLab, open to local schools, young students and companies.

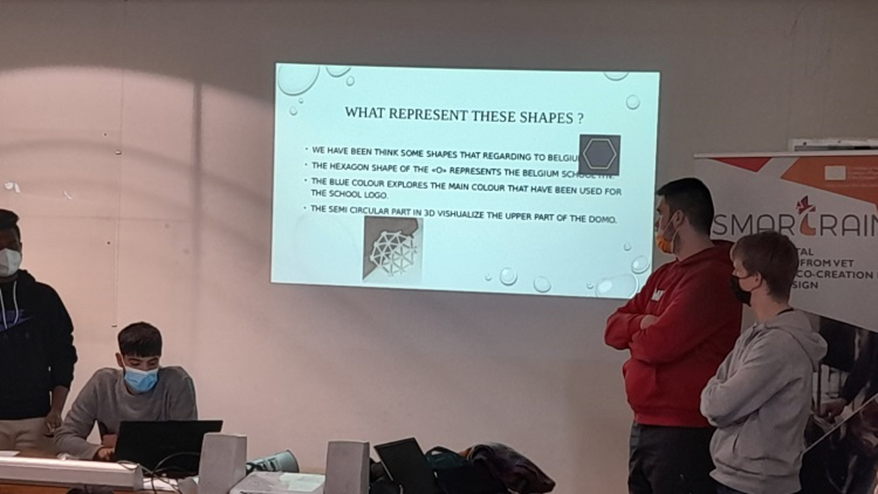

The students participating in the mobility were distributed in mixed groups, with a mix of nationalities in each team. Together with the teachers, they worked with guidelines to start the tasks in which each working group had to name their product and to think, co-create, design and make the logo related to their product, using 3D printing and laser cutting. Beforehand, the participants played a game to break the ice among them, in which they were aware of the limitations of language (which are not so much), of the different points of view in different environments, with people who think differently, etc.

On the other hand, during this day, each of the working groups presented their projects, based on the initial training they had in Belgium, on key concepts of circular economy. The products presented have different characteristics.

Once the logos were defined, each working team built prototypes with the materials and equipment available at the FAB LAB, experimenting with materials, processing, options, etc.

VISITS TO COMPANIES AND INSTITUTIONS

The visits included Enaip’s wood and furniture training workshops, the companies TABU, Riva1920, and the Politecnico di Milano.

VISIT TO ENAIP’S WORKSHOP

Enaip’s workshop is equipped with modern machinery for wood and furniture students. It works mainly on interior fittings for buildings:

Students and teachers exchanged views on processes, materials and designs they work on at the Centre, etc.

VISIT TO TABU

TABU is an acronym of the name of the Tagliabue family, who founded it three generations ago. It is an authentic wood tailoring company that is constantly researching into the processes of dyeing technology applied to dozens of wood species. Its core business is the production of wood veneers and the dyeing process, which guarantees colour homogeneity and infinite replicability: the certainty of colour is fundamental for a customer industry.

VISIT TO RIVA 1920

Founded in Brianza in 1920, Riva 1920 has been producing solid wood furniture of all kinds for over a hundred years. It produces everything from tables, to chairs, to bookcases, to entire kitchens: everything is made by specialized professional craftsmen, who create true works of art in wood. Riva is one of the companies that contributes most to reinforcing the perception of “Made in Italy” worldwide.

As indicated on its website, the RIVA CENTER is a striking building clad entirely in Siberian larch wood, which opened in 2010.

The cladding is the result of a design idea of Renzo Piano’s Building Workshop d carried out by Harvard University. Inside the building, you can visit a museum with lots of tools and tools for woodworking, a showroom and the PANGEA LAB with a very complete xylotheque.

A visit was made to the RIVA CENTER, one of the most emblematic facilities of the Italian company .

It is worth noting the existence of tables made of very old wood. The centrepiece of this space is the Antico table, 12 meters of 48,000-years-old Kauri wood from New Zealand , with an iron base designed by the architect Renzo Piano.

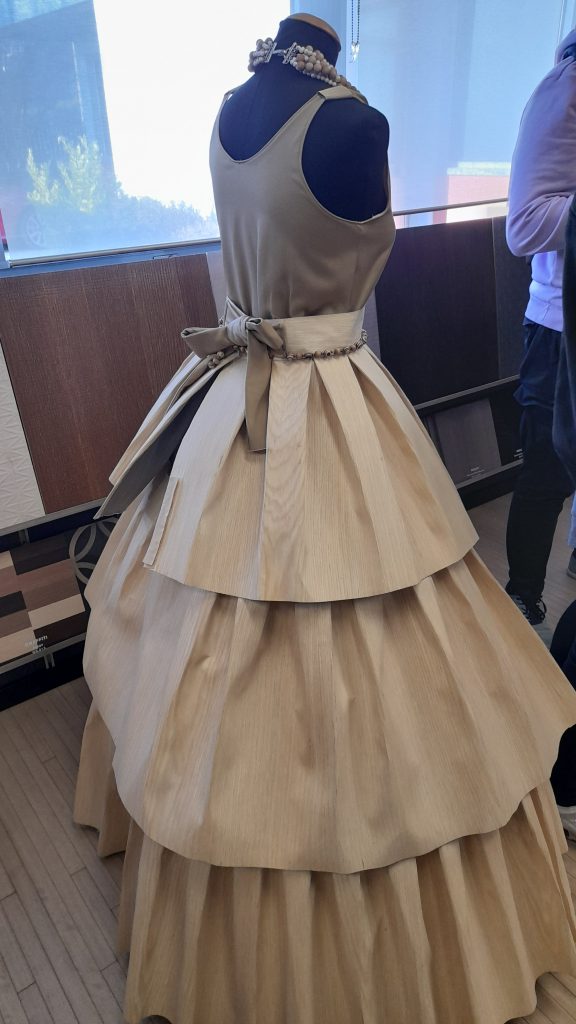

VISIT TO THE MILAN POLYTECHNIC

The group visited one of the world’s leading universities for DESIGN studies in all its dimensions. The SMARTRAIN project group visited the laboratory of the Wood Design course, as well as other laboratories of the School of Design. The person in charge of the subject explained the activities that carried out, design strategies, concepts, etc. of great interest for the whole group. A Colombian student of the Master’s in Design, specialised in the field of service design, told the group her personal story until she came to study in this centre and gave the students valuable advice about the existing possibilities.

It has been a very interesting mobility in terms of group and collaborative work, progress in certain aspects of the projects of the three groups, and a series of very enriching visits in terms of possibilities, ideas, materials, designs, to incorporate in their projects, etc.

The consortium, especially the Spanish group, showed the draft of the mobility planning to be held in May in Spain, which is preparing agenda schedule of activities focused on the final progress of the projects, f smart furniture concepts, and a series of visits to several companies of interest for the objectives of the SMARTRAIN project.